A Destiny of Electronics: Investigating Conductive-Type Polyimide Resin Materials

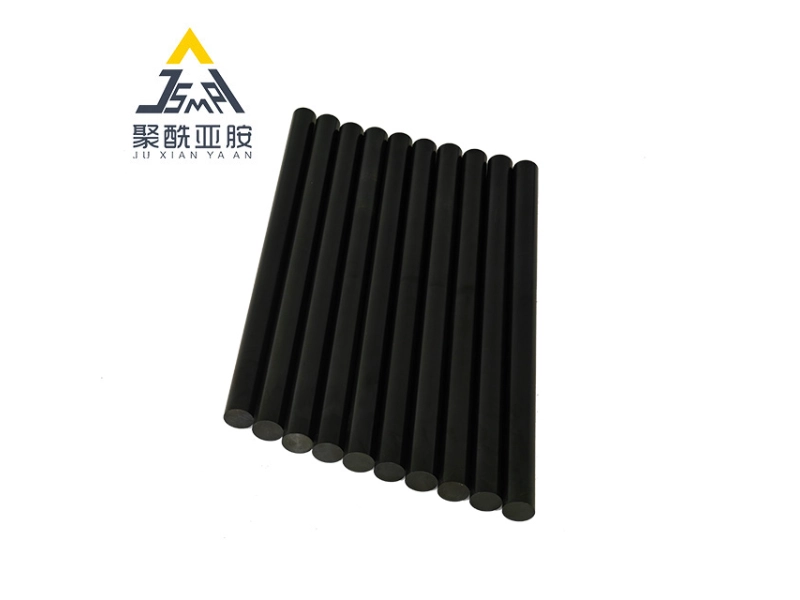

These fast developments within electronic materials have been laying the way for creative solutions throughout various industries. Among these developments, conductive polyimide resins have emerged as a game-changer, especially in the realm of high-performance applications. These resins are recognized for their exceptional thermal stability, mechanical strength, and versatility, rendering them perfect for demanding environments. The conductive polyimide rod is a remarkable manifestation of this technology, showcasing unique properties that can boost electronic designs.

Within aerospace, where performance and reliability is essential, the use of polyimide rods is more and more prevalent. Lightweight yet sturdy, these rods can withstand extreme temperatures and harsh conditions, rendering them suitable for applications in aircraft and spacecraft. The integration of conductive polyimide rods in aerospace components not only contributes to weight savings but additionally allows efficient electrical conductivity, essential for advanced electronic systems. In the future, the potential of conductive polyimide resins signifies a transformative shift in the way we utilize electronic materials in high-performance settings.

Overview to Conductive Polyimide Resins

Electrically-Conductive polyimide resins have become known as a revolutionary material in the electronic industry, especially due to their exceptional combination of electrical conductivity and heat resistance. https://www.hsjuxin-pi.com/category/products/polyimide-rod/ are engineered to include conductive fillers, allowing them to maintain their structural integrity while enabling efficient electrical performance. As technology develops, the desire for lightweight and tough materials expands, making conductive polyimide resins a crucial player in various applications, including bendable circuits and electronic components.

One of the most remarkable features of conductive polyimide resin rods is their fitness for the aerospace industry. In this field, the requirement for materials that can tolerate extreme conditions while providing consistent performance is critical. High-performance polyimide rods merely meet these stringent requirements but also offer substantial weight savings compared to traditional materials. This makes them perfect for applications such as thermal insulation, load-bearing components, and thermal management systems where both reliability and performance are of utmost importance.

The adaptability of electrically-conductive polyimide resin rods extends beyond aerospace, as they are growingly being employed in fields such as car manufacturing, telecommunications, and consumer electronics. Their ability to be formed into various shapes and sizes allows for creative designs in electronic devices. As research continues to evolve in this area, the future of conductive polyimide resins looks promising, opening up possibilities for next-generation electrical applications that focus on efficiency and durability.

High-Performance Polyimide Bars

Top-tier polyimide-based rods have appeared as a vital material in multiple applications due to their exceptional thermal stability and electrical conductivity. These rods are engineered to endure extreme temperatures while maintaining their mechanical integrity, which makes them ideal for challenging environments. These distinctive properties permit them to perform effectively in applications where traditional materials would not succeed, for instance in aerospace and advanced electronics.

In the aerospace industry, the requirement for low-weight and strong materials is critical. High-performance polyimide rods satisfy this demand by delivering the strength and resilience needed for structural components and electrical insulation. Such rods contribute to the performance and reliability of aerospace systems, where minimizing weight can significantly enhance fuel efficiency and overall performance. The ability to maintain functionality under extreme conditions renders these rods a favored choice among engineers and designers in aerospace manufacturing.

Moreover, the adaptability of high-performance polyimide rods enables customization to accommodate specific applications. Manufacturers can modify the properties of these rods, such as their conductivity and thermal resistance, to meet the precise needs of different industries. As technology advances and the demands for more efficient and durable materials increase, high-performance polyimide rods are set to play an important role in molding the future of electronics and other key sectors.

Uses in the Space Industry

Electrically conductive polyimide resin rods are growing significant attention in the aerospace sector due to their exceptional thermal stability and lightweight properties. These characteristics make suitable for high-efficiency applications where conventional materials might be inadequate. Designers are increasingly incorporating these rods in components that require endurance and resistance to severe conditions, such as in aviation wiring systems and structural components that face temperature challenges.

The use of conductive polyimide rods is also revolutionary in the design of advanced sensors and actuators used in aerospace applications. Their ability to conduct electricity while maintaining structural integrity allows for innovative design solutions. These rods facilitate the miniaturization of electronic systems, ultimately contributing to improved performance and efficiency in avionics and in-flight systems.

In addition, as the aerospace industry keeps to push the limits of technology with advancements in composite materials, conductive polyimide rods serve as a ideal complement. They can be easily integrated with multiple composite structures, enhancing their electrical properties without compromising weight or strength. This integration is vital for the next generation of aircraft, which demand more lightweight and efficient materials to meet rigorous fuel efficiency and performance standards.

Future Trends in Polyimide Technology

The future of electrically conductive polyimide resins is set for remarkable advancements, especially as sectors demand more long-lasting and effective materials. Advancements in polymer chemistry are resulting to the creation of advanced polyimide rods that exhibit superior mechanical properties and thermal stability. These advancements are vital for applications in challenging environments, such as space exploration, where materials must withstand extreme temperatures and stress while maintaining conductivity.

Moreover, the aviation industry is increasingly integrating conductive polyimide rods into their products, recognizing the need for lightweight yet robust materials. As aircraft strive for greater fuel efficiency and diminished weight, polyimide resins offer an ideal solution. Their ability to merge conductivity with lightweight characteristics makes them appealing for use in diverse aerospace applications, including cabling, monitoring equipment, and framework elements, facilitating enhanced performance and reliability in flight.

Moving forward, sustainability will have a significant role in the evolution of polyimide technology. With a growing emphasis on sustainable materials, research is focusing on developing biodegradable or repurposable polyimide resins. This shift not only tackles ecological concerns but also creates new avenues for premium materials that retain the advantageous properties of conventional polyimides, again solidifying their place in the next generation of electronic applications.